If your latest construction project requires safely elevating your team and their tools to regularly work at heights above 19 feet, a scissor lift will be a valuable piece of equipment to have on hand.

Scissor lifts are known to boost worksite productivity and help works remain safe by having everything they need on hand without the hassle and risk of repetitively climbing up and down ladders carrying their tools. Typical scissor lifts will elevate to heights of 19 ft - 59 ft. Additionally, some scissor lifts are designed to be operated on concrete slabs and others are designed for rough terrain. When purchasing a new or used lift, it’s important to understand which model best suits your company’s needs.

Of course, buying a new scissor lift or even renting a lift for an extended period of time can be costly so shopping for a gently used one can be a great cost-savings strategy. Before you jump in and take the first deal you find, it’s essential to do a complete safety check of the used construction equipment.

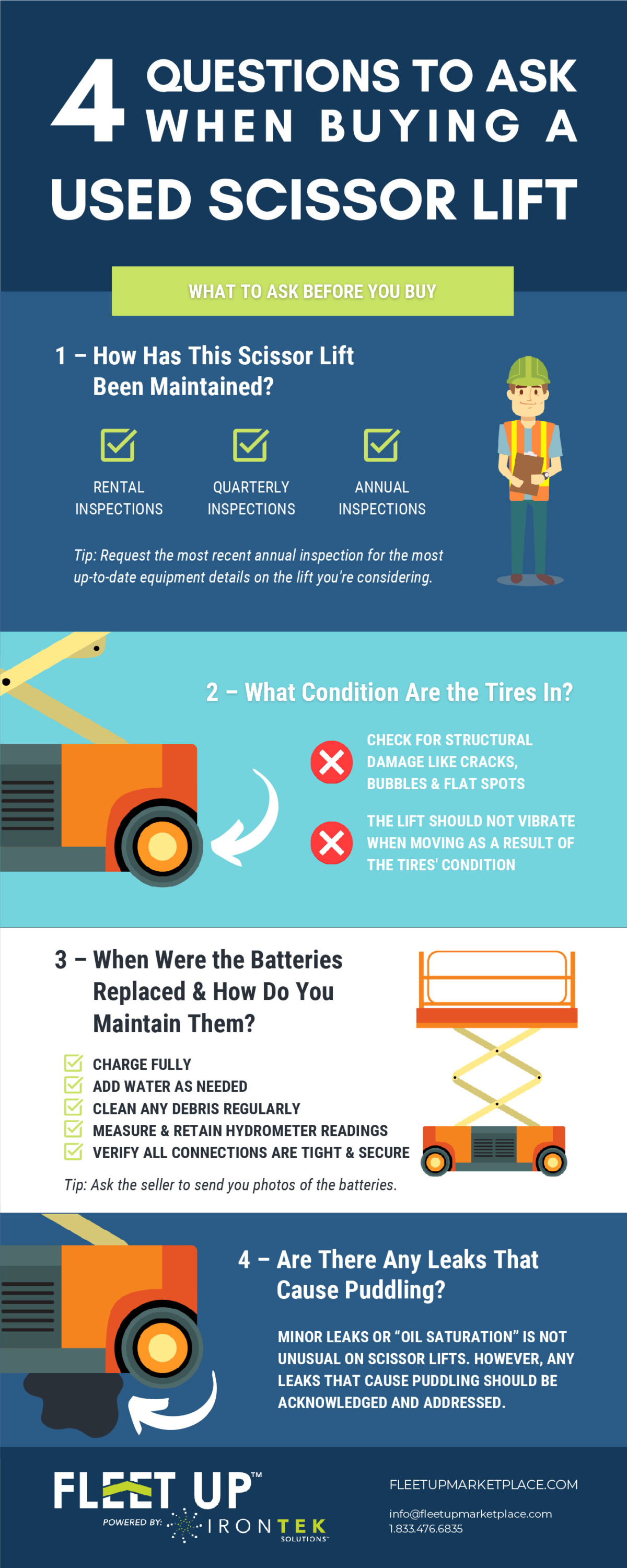

While there are various factors to consider when purchasing a used scissor lift, the primary categories to consider are:

Equipment maintenance and service history

Equipment tire safety

Equipment battery maintenance

Overall equipment condition and leaks

These areas are explained further in the infographic below.

Asking for company records of maintenance, service repairs, and accident reports is standard when purchasing used safety equipment and should be provided with no issues from a reputable seller.