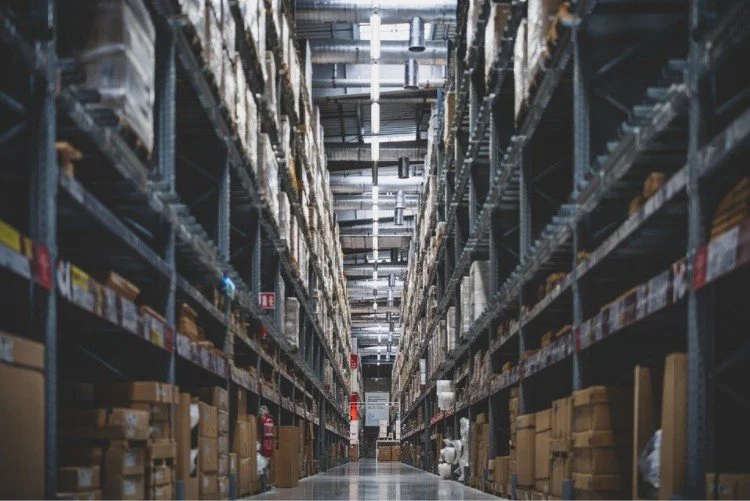

When running your own business you may have lots of stock and inventory that needs storing and sorting. The best way most businesses would deal with this is by getting a warehouse whether that is one you can purchase or even rent. Having a warehouse gives you great options when it comes to sorting out your inventory and stock, however, some people can forget to actually manage the warehouse too or maybe you are just unsure what you need to think about when managing your warehouse. If this is the case then these few tips can help you to understand what to do when managing your warehouse.

Source: Pixabay

Make sure to keep your warehouse clean and tidy

Keeping your warehouse clean and tidy is not only important for health and safety but also to make sure you can remain efficient. When running a big warehouse sometimes orders can get misplaced or knocked down somewhere and lost. By tidying your warehouse with the help of a professional warehouse cleaning service you can locate all your stock, organise your orders, and make sure they are either sent out or, at least, you have your stock back should you have already replaced the items for the customer.

Keep your warehouse organised

It can be easy for a warehouse to get unorganised, especially if it is a larger one, but you do need to try and have some sort of organisation in place. Whether that be grouping similar items or grouping things based and what is usually bought together to make it easier to find. There are many ways you can organise your warehouse. It is just a case of finding what works best for your style of working and what sort of stock you are storing.

Work out how to move your stock

When managing your warehouse you need to make sure you are able to safely and easily move around your stock whether that is for preparing orders or restocking on delivery day. In order to do this you should try and get some forklifts to help move your stock, when moving stock with forklifts you can streamline and increase efficiency for your drivers by getting forklift mounted computers. This will give your drivers something to use that is up to the task and hardy while also allowing them to manage inventory and update stock lists etc.

You should also have handheld wheeled devices too to help with moving of stock for those things that a forklift would not be necessary for. Moving stock can be dangerous, this could be from falling stock or just by lifting and carrying something wrong so make sure you have all the relative checks and certificates in place to make sure staff are safe when handling stock and machinery.

If you are looking after stock for your business and you are using a warehouse to do so then make sure you are managing your warehouse properly. If you are unsure how then these few tips should help to get your started and make sure you understand what can be done to effectively manage your warehouse.