Manufacturing operations tend to revolve around processing inventory and maintaining production lines. But measurement is a significant element of any operation. Everything needs to work together in a compatible manner.

Accuracy in manufacturing can take multiple forms. It can involve sales data, inventory tracking, and parts measurements. Getting any of these wrong can lead to disaster, forcing the firm out of business.

This post explores some of the reasons why accuracy matters for manufacturers and how you can improve measurements and data collection at your firm.

It Helps To Keep Track Of Inventory

Most manufacturers keep electronic records of physical inventory. Computer programs tell them what they have, letting them manage their sales, forecasting, and supply chain. Failure to do so can lead to unhappy customers and unproductive employees.

Unfortunately, inventory tracking doesn’t always work out perfectly. Several factors can and do get in the way. Therefore, firms should use robust integrated systems that deal with both the electronic and physical sides of their operations. They should have accurate data concerning what is already in-store, and what’s on the way.

Most inaccuracies occur before inventory reaches the warehouse. Vendors may ship the wrong number of goods from the source. Having proper inventory management tracking at the warehouse level prevents this.

It Refines Manufacturing Processes

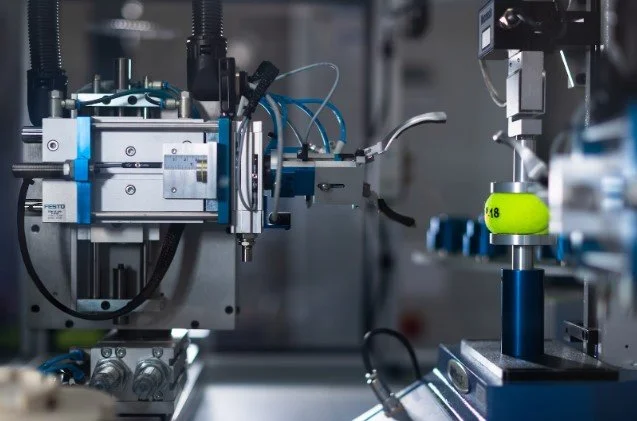

Accuracy is also essential for refining manufacturing processes and making them more competitive. Firms need to ensure their equipment is compatible with bespoke production lines and that their products are the right shape and size. A lack of proper measurement can prevent this from occurring, leading to awkward techniques that reduce the quality of the final product.

Many brands fail to use a portable CMM service company. Because of this, they don’t really know how large or small their surfaces and items are. Their production lines could be poorly specified, but they wouldn’t know it.

Proper measurement eliminates these issues. System designers have more accurate data they can work with. This advantage lets them develop designs that more closely meet your production, consumer, and marketing goals.

It Improves Sales Forecasting

Manufacturers need to know precisely how many resources they should dedicate to operations. This way, they can keep their costs down while meeting consumers’ needs.

Unfortunately, most manufacturers do not implement accurate sales forecasting. They don’t have a clear picture of how many products they need to manufacture over the next month or quarter.

This ignorance puts them at a significant disadvantage. Many manufacturers wind up with too much inventory which they then have to sell to vendors at a discount to recoup their losses.

Integrated demand forecasting which takes multiple data streams into consideration helps to prevent this from occurring. Computer software stitches information from various sources together to give managers a clearer picture of their production requirements.

Critically, these systems don’t rely on antiquated historical forecasting models. That’s because they understand that solely using past data and extrapolating it to the present leads to inaccurate predictions. Modern software follows consumer trends unfolding right now to avoid this issue.